|

AKW high-performance concrete mixing equipment is used to efficiently and evenly mix UHPC materials. UHPC has ultra-high strength and density, and its mix ratio often contains a large amount of fine powder (such as cement, silica fume, etc.) and fibers (such as steel fiber, carbon fiber, etc.). Therefore, UHPC mixers need to have strong mixing power and unique mixing structure to ensure that these ingredients can be evenly mixed. For example, some advanced UHPC mixers use the planetary mixing principle, through multiple mixing arms moving at different trajectories at the same time, which can effectively break the powder agglomeration and make the fibers evenly dispersed in the matrix.

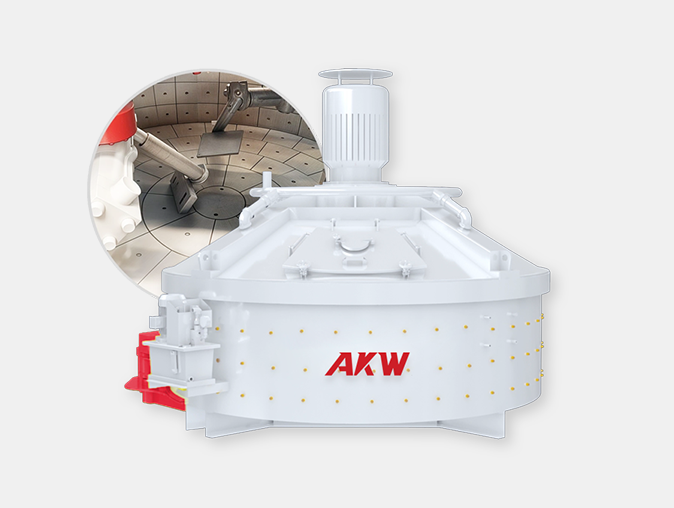

AKW planetary concrete mixer for UHPC mixing[Model]: AMP50/AMP100/AMP150/AMP250/AMP330/AMP500/AMP750/AMP1000 Output Capacity: 50L/ 100L/150L /250L/330L/500L/750L/1000L

High uniformity: UHPC materials usually require highly uniform mixing to ensure their performance. UHPC mixers achieve all-round, 360-degree mixing without dead ends for materials, so that cement, aggregates, fibers, etc. are evenly distributed, greatly improving the quality and performance of concrete.

High efficiency: Compared with traditional mixers, UHPC mixers are more scientifically designed and have faster mixing speeds. They can complete the mixing of materials in a shorter time, thereby improving production efficiency. Convenient unloading and transfer  AKW Intensive mixer for UHPC premix mixing:Intensive mixer: The first choice for users who require better uniformity and efficiency. The intensive mixer is a UHPC premix mixer with a three-dimensional mixing mode. 100% of the materials are mixed and the mixing efficiency is high. High degree of automation, reducing labor Efficient and stable 100% mixing uniformity Convenient unloading  UHPC Mixers are used for the production of

|

|