AKW refractory mixing and preparation system

Mixing technology (four different types of refractory mixers)

Granulation technology (R series high-power mixer)

Heating system (uniform temperature distribution of refractory raw materials)

Batching system: to achieve accurate batching of raw materials

Control system: computer-controlled process parameters are stable, eliminating product quality fluctuations

High-intensity mixing effect, high mixing efficiency, uniform mixing, and no dead angles in mixing.

AKW has developed and designed five different types of refractory mixers, with mixing capacities ranging from 1L to 7000L and batch (intermittent) mixing times ranging from 1 minute to 15 minutes, to meet the mixing and preparation needs of various materials in the refractory industry. AKW refractory mixers not only ensure efficient mixing and homogeneity of materials, but also ensure excellent stability between batches.

|

Planetary mixer/vertical shaft fast mixer AMP vertical planetary mixer is widely used in the mixing of various amorphous refractory materials such as castables, ramming materials, and profiled materials. Akw vertical planetary mixer has the following advantages: 1. The mixing tool covers the entire mixing drum within 5 seconds, without dead corners, and the mixing is uniform. 2. A special unloading sealing cover is used to effectively prevent dust from flying. 3. Dust removal system to prevent dust from overflowing during mixing. 4. Special wear-resistant lining with a flatness of up to 2-5mm, the material in the mixing drum is discharged cleanly with a low residual rate. 5. Optional special dust collector. Capacity: 5 to 5000kg Mixing time: 3-10 minutes |

|

|

|

|

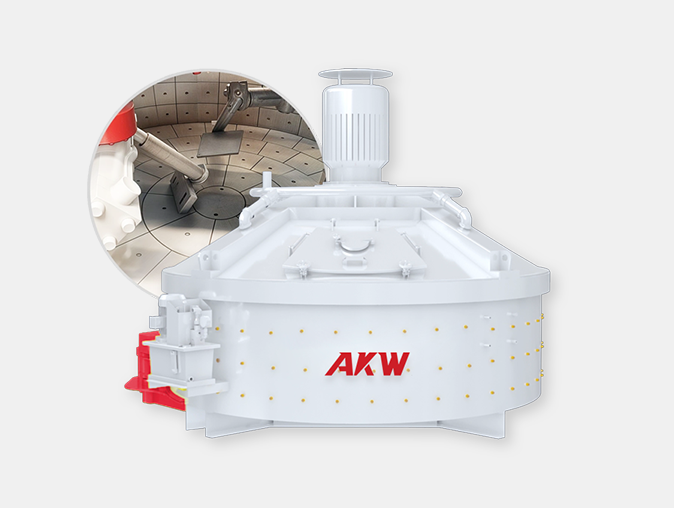

R type intensive mixer R-type inclined intensive mixer is used for the mixing, mixing and granulation of various refractory raw materials. It has stable and excellent mixed material quality and stable uniformity in high-alumina bricks, magnesia-carbon bricks, and continuous casting three major parts (nozzles, etc.). Akw inclined strong mixer has the following advantages: 1. Best mixing uniformity 2. Shortest mixing time 3. Mixing, granulation, heating and cooling technology 4. Countercurrent mixing principle, three-dimensional mixing technology 2. Reliable sealing Capacity: 1-6000L |

|

|

|

High speed muller mixer

Designed for the characteristics of the ceramic and refractory industries, the roller is designed to be a liftable structure that can adjust the pressure and has the function of oil pressure overflow DL high-speed roller mixer has the following features: 1. The material is rolled more thoroughly and ideally 2. The mixed material has a higher density, fewer pores, and superior performance 3. The main stirring is combined with the high-speed stirring differential mode 4. The double rollers have adjustable pressure and pressurization functions 5. High degree of automation 6. Novel and beautiful appearance design |

|

High-speed mixer for refractory materials

The high-speed mixer is upgraded from the planetary mixer. The rotor speed is faster, up to 400-500rpm. Compared with the planetary mixer, the mixing efficiency is higher, and the unit cost is about 40% lower than that of the strong mixer. The high-speed mixer for refractory materials is widely used for mixing shaped refractory materials, mainly suitable for various refractory bricks: clay bricks, high-alumina bricks, lightweight bricks, insulation bricks, corundum bricks, etc. 1. Fast mixing speed, uniform mixing, high efficiency 2. Various liquid and powder input ports can be installed according to customer requirements. 3. Equipped with a large inspection door for easy cleaning. 4. Sampling ports can be installed according to customer requirements. Capacity: 100 to 1000 kg |

|

|

|

Twin-shaft refractory mixer

Rapidly mixing refractory castables, horizontal shaft mixers are designed to mix dry, semi-dry and low moisture refractory castables uniformly and efficiently. These batch mixers are available in capacities from 750L-7000L with a maximum batch weight of 12,000 lbs. All components from the paddles and mixing shafts to the V-belt drive system are made of rugged materials and engineered for maximum durability. The interior is lined with wear-resistant steel and cast Ni-Hard to extend equipment life. |

Pressed bodies of various bricks, including hot mixes

Insulating refractory brick bodies

Pellets of isostatically pressed products

Dense vibrating bodies, cast sheets, ramming and spraying mixtures

Insulating mixtures

Mortars and putties

Dry mixtures

Prefabricated parts

Mixtures of ceramic fiber materials

Mixtures and granules of oxide and non-oxide ceramic materials