AKW laboratory intensive mixer model CR05 for ceramic powder mixing and granulation

CR05 ceramic powder mixing and granulation machine technical parameters

Model: R05 laboratory granulator

Ceramic powder granulator price: according to configuration

Place of shipment: Qingdao, Shandong Province, China

Granulation volume/batch: 10-50 liters

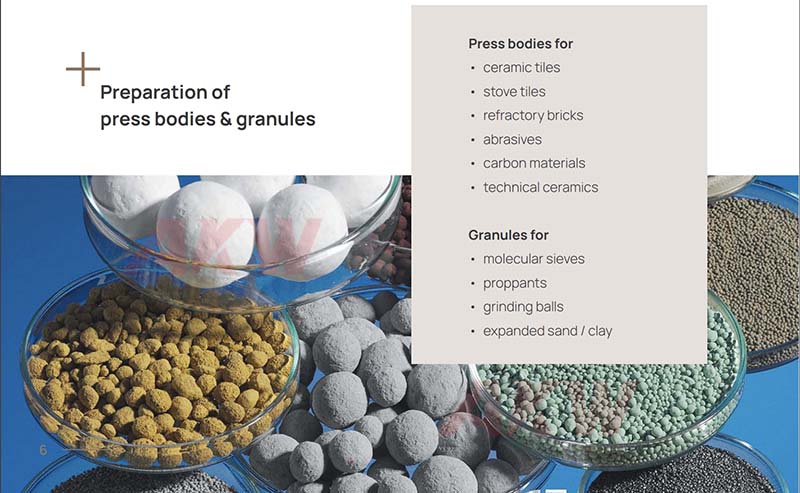

Application areas: Molding compounds, molecular strainers, proppants, varistor compounds, dental

compounds, cutting ceramics, grinding agents, oxide ceramics, Non-oxide ceramics,

composite materials, silicate technical ceramics, grinding balls, ferrites, et

Ceramic powder dry granulation is a method of making ceramic powder into granules, and the process usually includes the following steps:

Raw material preparation: Select ceramic powder suitable for dry granulation and ensure that its particle size, chemical composition and physical properties meet the requirements.

Additive mixing: Add appropriate amount of additives such as binders, lubricants, etc. to the ceramic powder as needed to improve the granulation effect.

Dry granulation: put the mixed ceramic powder into the dry granulator, and agglomerate the powder into particles through mechanical force.

Particle screening: sieve the granulated particles to remove oversized or undersized particles to obtain the required particle size distribution.

Particle drying: dry the sieved particles to remove moisture from the particles and improve the strength and stability of the particles.

Particle packaging: package the dried particles for storage and transportation.

Advantages of ceramic powder dry granulator:

Even mixing: the turbulent three-dimensional mixing technology can complete the mixing and kneading processes in the same device to ensure that the mixed materials are fully uniform.

Save time: compared with other mixers on the market, the AKW series granulator can save at least 3 times more time and significantly improve production efficiency.

Simplify the process flow: simplify the process flow, reduce equipment investment and operating costs.

Improve production efficiency: dry granulation can be carried out continuously, with high production efficiency, suitable for large-scale production.

Improve product quality: dry granulation can control the size and shape of particles and improve product quality and stability.

Reduce environmental pollution: Dry granulation does not require the use of solvents, so it can reduce environmental pollution and meet environmental protection requirements.

It should be noted that the effect of ceramic powder dry granulation is affected by many factors, such as the properties of ceramic powder, the type and amount of additives, the type and parameters of the granulator, etc. Therefore, when performing ceramic powder dry granulation, it is necessary to optimize and adjust according to the specific situation to obtain the best granulation effect.