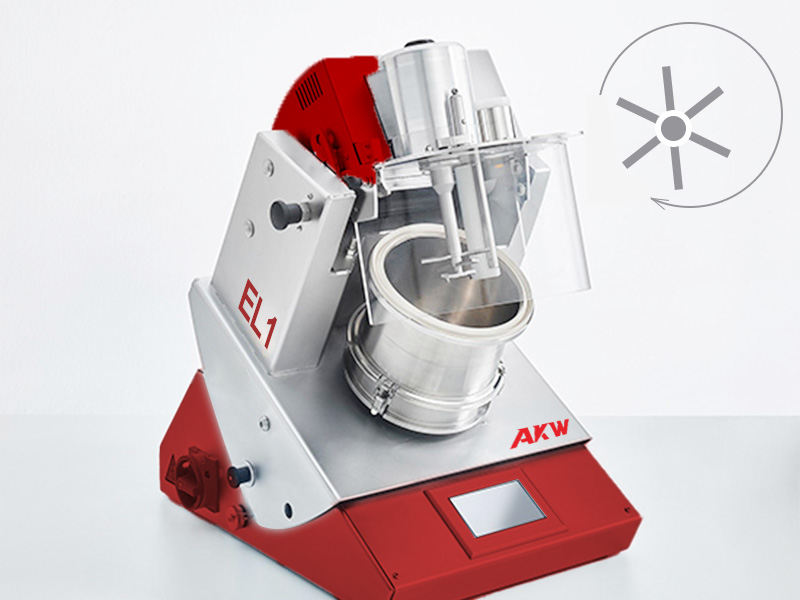

The laboratory intensive mixer uses the principle of countercurrent 3D mixing technology to achieve the best mixing uniformity in the shortest time. The high-speed rotor, the mixing disc tilted at a specific angle, and the multifunctional scraper work together to adjust the speed of the running mixer and realize a staggered mixing process. Stainless steel contact parts Optional Teflon pan Operating incline: 30°, 20°, 10°, 0° via adjustable hinge 1 L / 1.6 kg capacity

Mixing

Granulating

Slurring

Coating

Reacting

Dispersing

Heating

Vacuum

Cooling

Fibrification

lab intensive mixer does not produce stratification during mixing; the material circulation rate reaches 100% with one rotation of the mixing disc

Only one mixing tool is needed to achieve the best mixing effect

Various consistencies can be prepared in the mixer, from dry to plastic and pasteWide range of applications - meet the mixing and preparation requirements of different industries and various materials

High mix quality in extremely short mixing times

Unlimited scalability – industrial amplification of test results, linear conversion of test results to industrial scale

The output and mixing intensity of the Power Mixer can be adjusted independently: the Power Mixer mixes without separating the material because 100% of the material is involved in the mixing each time the mixing vessel rotates. High-speed mixing: optimal dispersion of fibers; optimal mixing of powdered fines; production of suspensions with a high solids content Medium-speed mixing: high quality mixtures can be obtained Low-speed mixing: lightweight additives or foams can be gently added to the mixture. |

The mixing, kneading, granulation and balling process can be completed in the same intensive mixer, and the mixture can be fully uniform. It has few processes, simple operation, and can quickly prepare the required particles in a short time.

|

AKW heating/cooling/vacuum high-power mixer retains all the advantages of high-power mixer. According to the application of different industries, it superimposes heating, cooling and vacuum process technology steps to complete the mixing, granulation, coating, reaction, drying, exhaust, cooling and other material in the same equipment. Molding sand Battery lead paste High-density particles Sludge containing water or solvent Sludge containing metal Friction lining Soap

AKW Intensive mixer can achieve an output of hundreds of tons per hour, and also meet the needs of various R&D institutions, colleges and enterprises for one-liter mixers in laboratories! The laboratory mixer meets all the functions of a high-power mixer.

|

Model |

Mixed Volume/L |

Maximum volume/Kg |

Discharging |

Batch |

Heating |

|---|---|---|---|---|---|

|

EL01 |

0.3-1 |

- |

manual |

batch |

⚫ |

|

EL5 |

2-5 |

8 |

automatic |

batch |

⚫ |

| EL10 |

4-10 |

12 |

automatic |

batch |

⚫ |

| R02 |

2-5 |

8 |

automatic |

batch |

⚫ |

| R04 |

4-10 |

12 |

automatic |

batch |

⚫ |

| R05 |

8-25 |

30 |

automatic |

batch |

⚫ |

| R08 |

18-50 |

60 |

automatic |

batch |

⚫ |

| R09 |

35-100 |

120 |

Hydraulic center |

batch |

⚫ |

| RV09 |

50-100 |

240 |

Hydraulic center |

batch |

⚫ |

| R11 |

80-250 |

400 |

Hydraulic center |

batch |

⚫ |

| RV11 |

375 |

600 |

Hydraulic center |

batch |

⚫ |

| R15 |

500 |

800 |

Hydraulic center |

batch |

⚫ |

| RV15 |

750 |

1200 |

Hydraulic center |

batch |

⚫ |

| R19 |

1125 |

1800 |

Hydraulic center |

batch |

⚫ |

| RV19 |

1500 |

2400 |

Hydraulic center |

batch |

⚫ |

| R20 |

1250 |

2000 |

Hydraulic center |

batch |

⚫ |

| R24 |

2250 |

3600 |

Hydraulic center |

batch |

⚫ |

| RV24 |

3000 |

4800 |

Hydraulic center |

batch |

⚫ |

| R29 |

4500 |

7200 |

Hydraulic center |

batch |

⚫ |

| RV29 |

5250 |

8400 |

Hydraulic center |

batch |

⚫ |

* Required

Please fill in the relevant information correctly, we attach great importance to your inquiry, it is very important to us!