AKW offers lab mixers from 1 liter up tp 10-liter capacity. Mixers for research, development, and small production The laboratory mixers of the EL series are available in sizes of 1 to 10 liters. They have all the features of the multifunction intensive mixer mixing system and can be used for a great variety of challenging processing applications.

Mixing

Granulating

Slurring

Coating

Reacting

Dispersing

Heating

Vacuum

Cooling

Fibrification

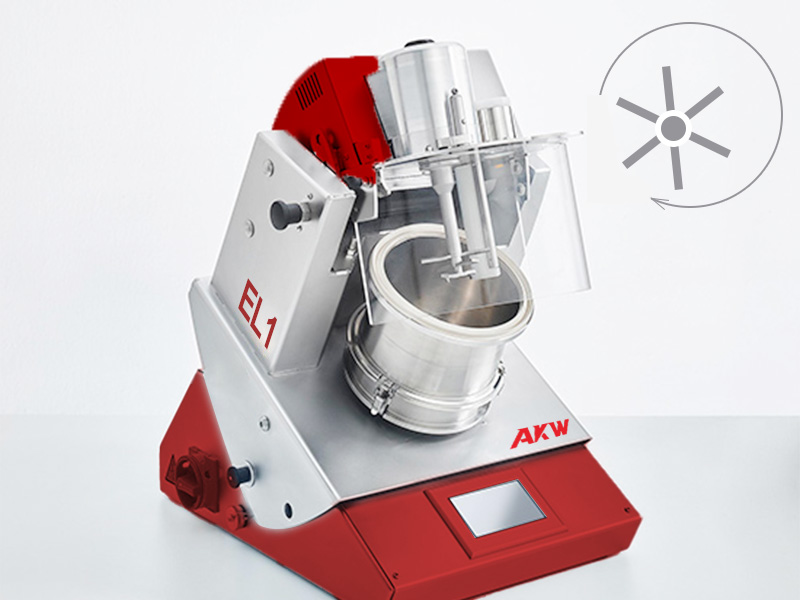

Intensive mixer, 5-liter capacity. The new EL5 mixer is smaller, lighter and smarter than its proven previous model, with the same performance and robustness. Simple operation, scale-up capability, integrated tilt adjustment and well thought-out options for daily laboratory operation. Upgrades include recipe management, data acquisition and network capability. This new 5 liter machine rounds off the portfolio of the AKW laboratory mixer series. [Features:] Mixing vessel: stainless steel Mixing tool: star-type rotor, modular design, made of stainless steel Mixing incline: adjustable 0-30° Control system: Basic Touch Control Mixing temperature: max. 180°C |

High-intensity mixer, 10-liter capacity With enhanced operating comfort Flexible high-performance mixing system for challenging tasks in the fields of research, development and small-scale production Process materials from dry to plastic and pasty can be processed.

[Applications] The multi-functional mixing system can be used for many different applications, e.g. for mixing, granulating, coating, kneading, dispersing, dissolving, defibering and many more. Industrial scale-up of test results is possible. Stainless steel contact parts Operating incline: 30°, 20°, 10°, 0° via wedge 10 L / 16 kg capacity |

The versatile 1-liter mixer Flexible high-performance mixing system for challenging tasks in the fields of research, development and small-scale production Process materials from dry to plastic and pasty can be processed. Stainless steel contact parts Optional Teflon pan Operating incline: 30°, 20°, 10°, 0° via adjustable hinge 1 L / 1.6 kg capacity [Applications] The multi-functional mixing system can be used for many different applications, e.g. for mixing, granulating, coating, kneading, dispersing, dissolving, defibering and many more. |

|

Model |

Mixed Volume/L |

Maximum volume/Kg |

Discharging |

Batch |

Heating |

|---|---|---|---|---|---|

|

EL01 |

0.3-1 |

- |

manual |

batch |

⚫ |

|

EL5 |

2-5 |

8 |

automatic |

batch |

⚫ |

| EL10 |

4-10 |

12 |

automatic |

batch |

⚫ |

| R02 |

2-5 |

8 |

automatic |

batch |

⚫ |

| R04 |

4-10 |

12 |

automatic |

batch |

⚫ |

| R05 |

8-25 |

30 |

automatic |

batch |

⚫ |

| R08 |

18-50 |

60 |

automatic |

batch |

⚫ |

| R09 |

35-100 |

120 |

Hydraulic center |

batch |

⚫ |

| RV09 |

50-100 |

240 |

Hydraulic center |

batch |

⚫ |

| R11 |

80-250 |

400 |

Hydraulic center |

batch |

⚫ |

| RV11 |

375 |

600 |

Hydraulic center |

batch |

⚫ |

| R15 |

500 |

800 |

Hydraulic center |

batch |

⚫ |

| RV15 |

750 |

1200 |

Hydraulic center |

batch |

⚫ |

| R19 |

1125 |

1800 |

Hydraulic center |

batch |

⚫ |

| RV19 |

1500 |

2400 |

Hydraulic center |

batch |

⚫ |

| R20 |

1250 |

2000 |

Hydraulic center |

batch |

⚫ |

| R24 |

2250 |

3600 |

Hydraulic center |

batch |

⚫ |

| RV24 |

3000 |

4800 |

Hydraulic center |

batch |

⚫ |

| R29 |

4500 |

7200 |

Hydraulic center |

batch |

⚫ |

| RV29 |

5250 |

8400 |

Hydraulic center |

batch |

⚫ |

* Required

Please fill in the relevant information correctly, we attach great importance to your inquiry, it is very important to us!