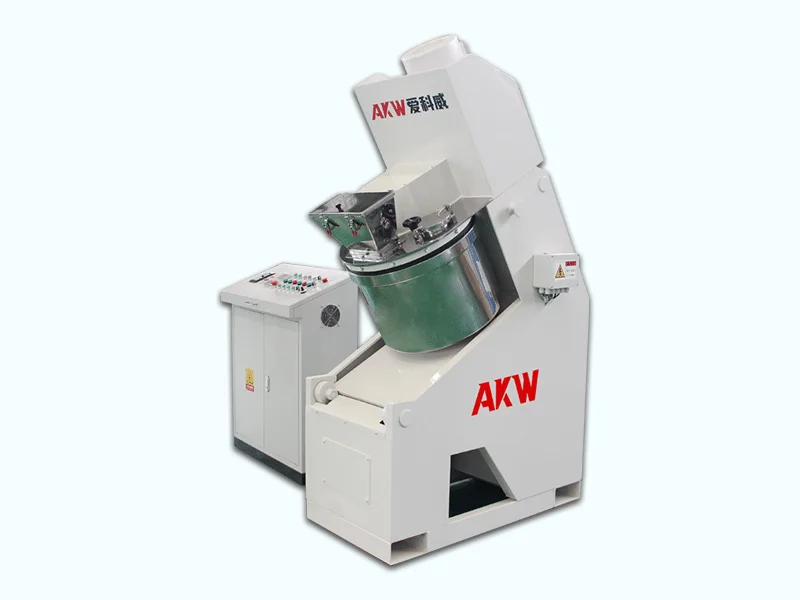

Lithium battery material selection mixing equipment, this intensive mixer is definitely worth your in-depth understanding. Below we give five reasons for choosing it from the aspects of performance and economy.

The first highlight is its three-dimensional countercurrent mixing technology.

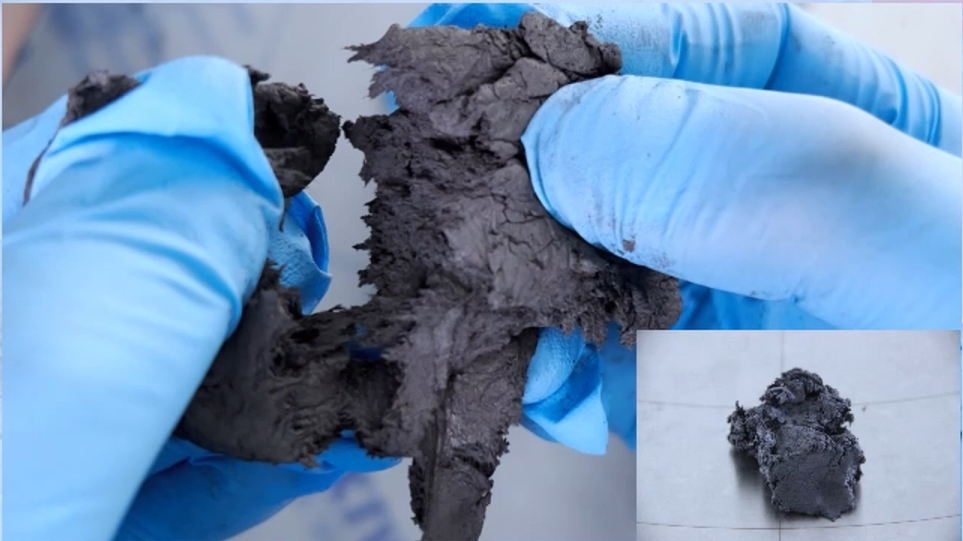

Through multi-directional rotational motion, the material is subjected to stronger shear and kneading forces during the mixing process, thereby achieving faster and more uniform mixing.

The battery may have problems of capacity decay too fast or unstable performance during use. This lithium battery intensive mixer can ensure that the parameters of the mixed materials are consistent, and the battery quality is guaranteed from the source.

Compared with traditional mixing equipment, lithium battery intensive mixer can knead and granulate at the same time. This means that the same equipment can complete multiple steps, and the production efficiency is doubled.

For you as a manufacturer of lithium-ion batteries, cost savings, quality improvements, and sustainability are currently key topics. Gigafactories for battery production place new demands on the processes – in particular when it comes to manufacturing the electrodes. Process technology from AKW will take you further and will open up a whole new world of opportunities.

The quality of the electrodes influences the performance capacity of your storage cells. This is where your challenge lies, because the production of a first-class electrode mix – slurry, plastic body, or also a structured dry mix – is an exacting task.

AKW can offer you the right solution – regardless of whether the electrode mixes is processed wet or dry.

The production efficiency of lithium battery intensive mixer is three times higher than that of ordinary equipment on the market, which greatly shortens the production cycle.

The uniformity and ball formation rate of battery positive and negative electrode material particles are also an advantage that cannot be ignored. In the granulation process of lithium battery materials, the particles are required to be uniform in size and high in strength, which will directly affect the performance of lithium batteries.

The fully enclosed design not only ensures that there is no dust pollution during the production process, but also reduces material waste. More importantly, the convenient maintenance reduces downtime, further improving production efficiency and equipment life.